Our Story

Uphold quality priority, blaze corporate glory.

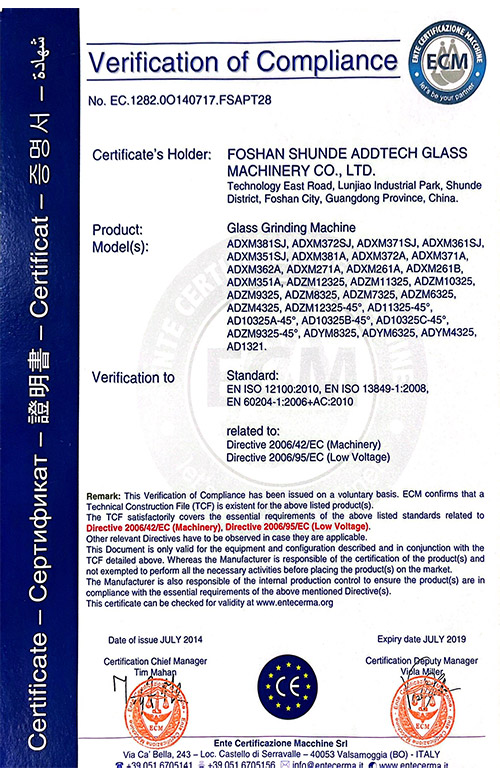

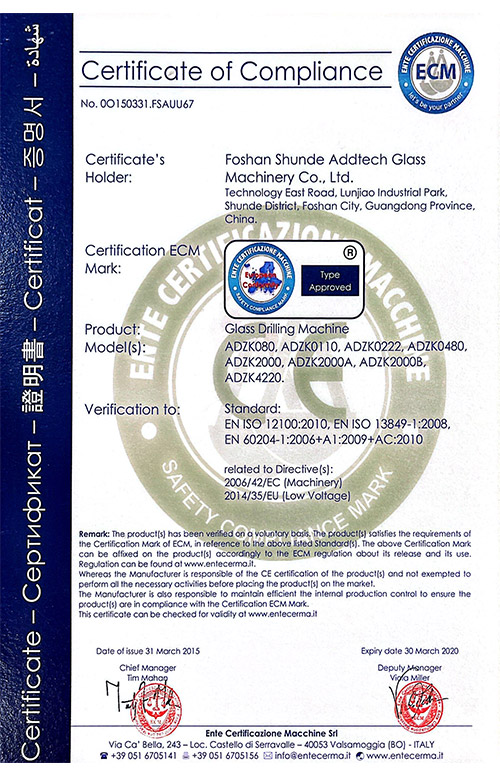

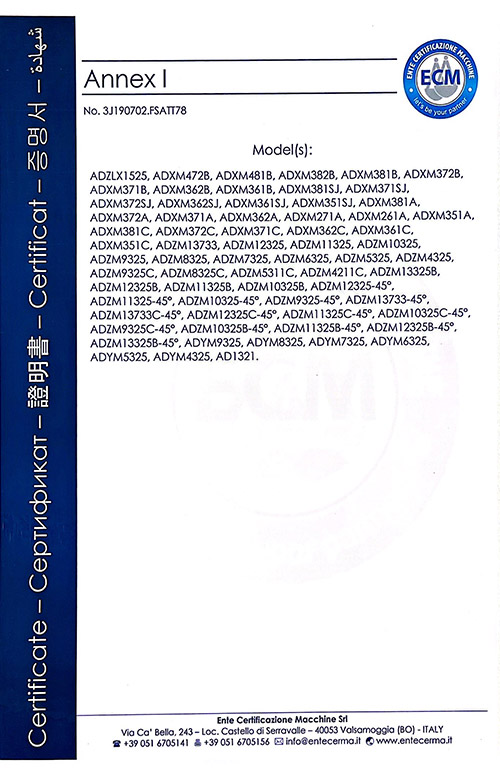

Founded in 2007, located in Shunde District, Foshan City, Guangdong Province, ADDTECH GLASS MACHINERY CO.,LTD is specialized in researching and manufacturing high precision glass processing equipment. With excellent stability and easy maintenance, ADDTECH nowadays has defined as national high-tech company and obtained the EU CE certification.

Click To Play

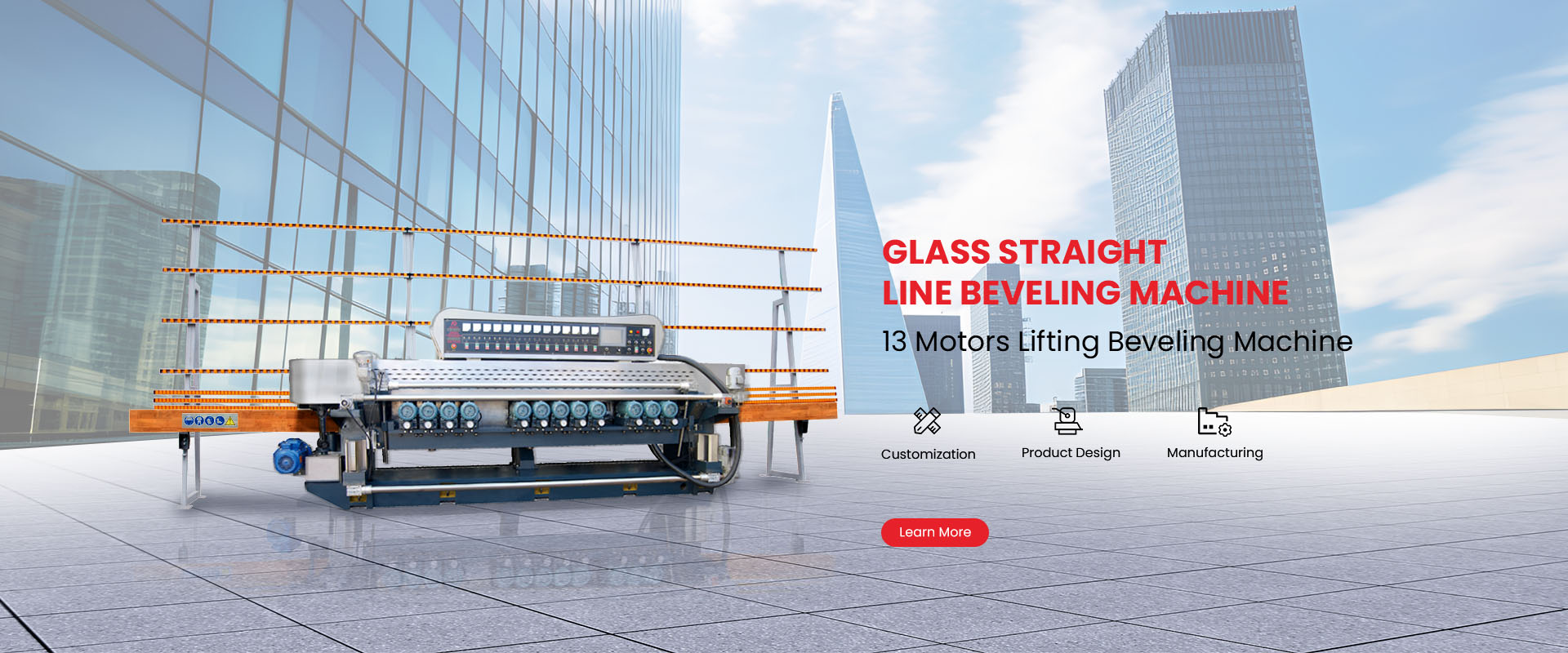

Product Center

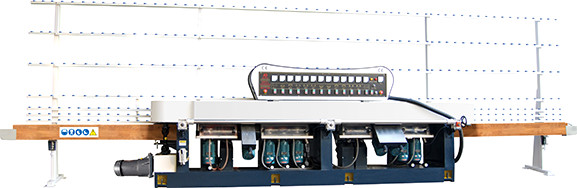

Glass Edging Machine Line

Certificate

Innovation

Adhering to innovation and product quality as the core competitiveness, ADDTECH has formed an experienced and highly innovative technician team, which has obtained more than ten invention patents in China. With these innovative technologies, ADDTECH have greatly improved the progress of the glass processing industry.

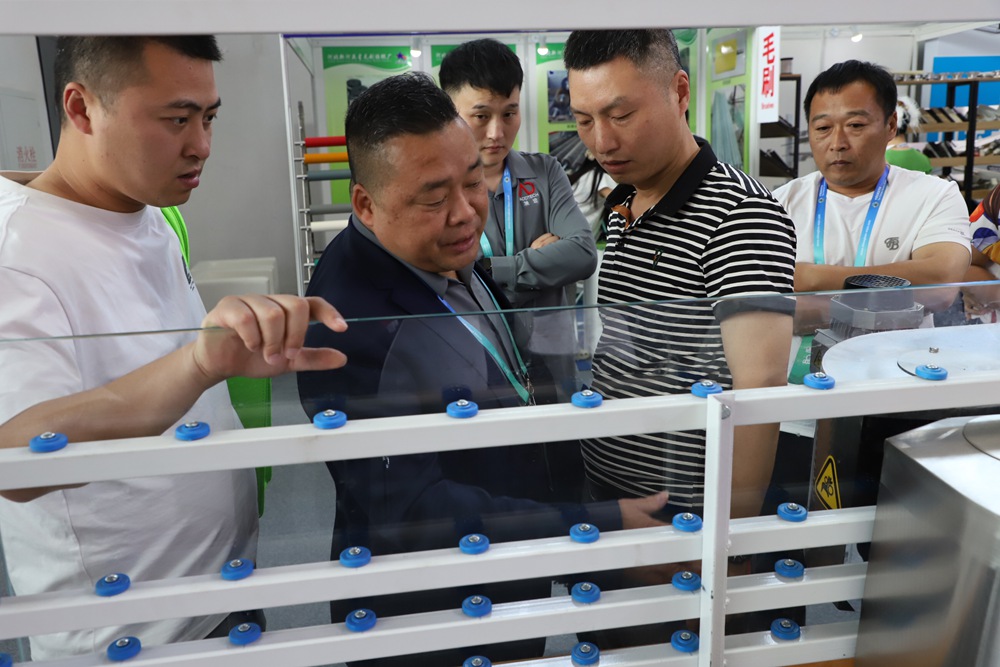

Factory

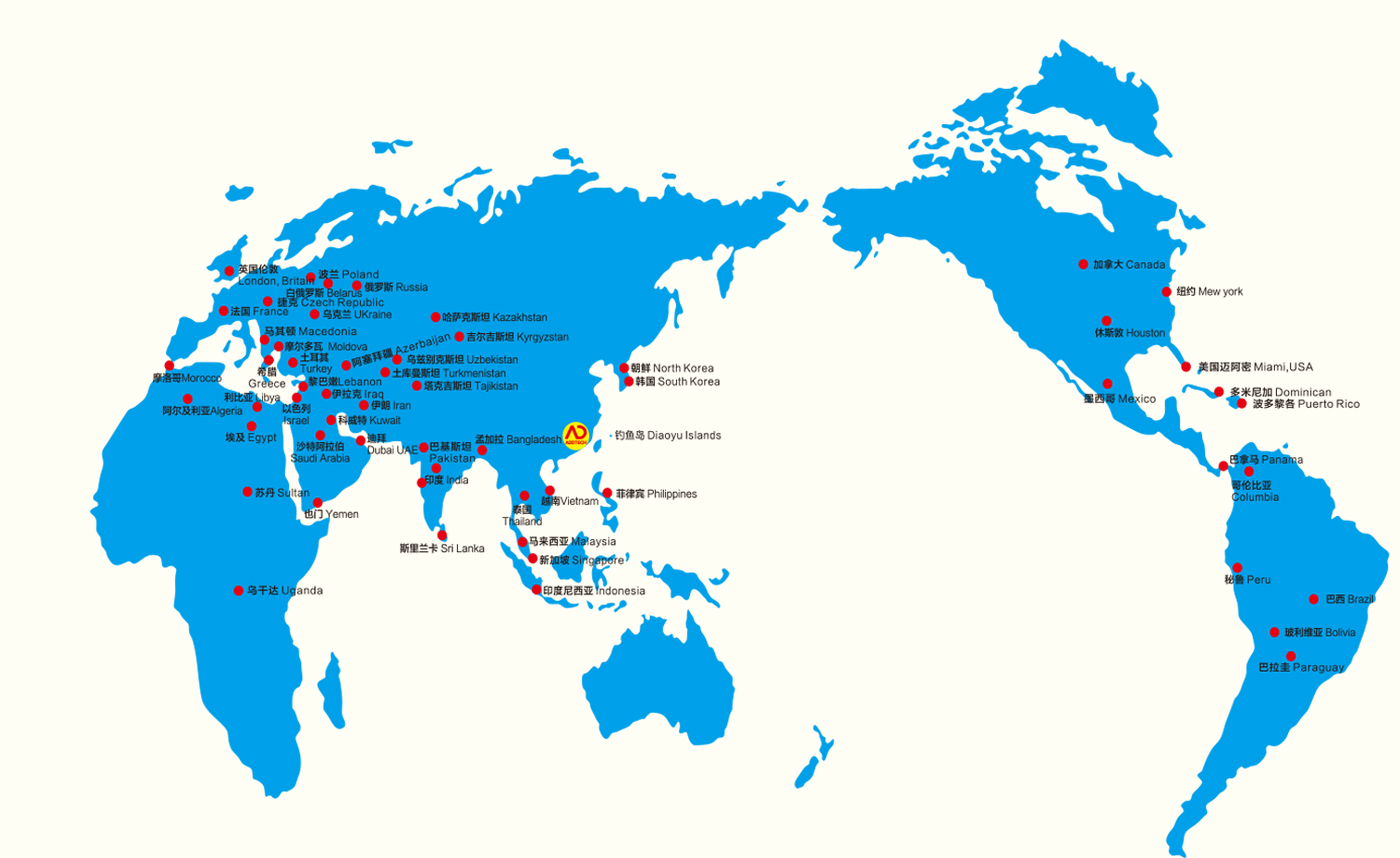

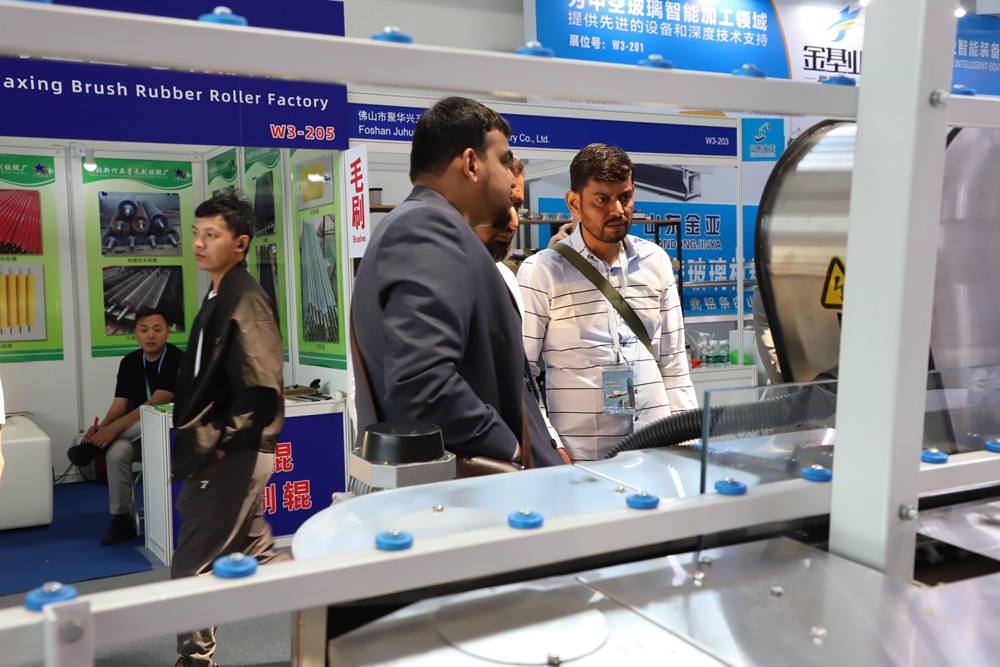

Cooperations Over The World